The pig system is a widely used pipeline technology that enhances efficiency, reduces waste, and improves maintenance processes across various industries. This system utilizes a specialized device, known as a “pig,” which travels through pipelines to clean, inspect, and recover residual products. Industries such as oil and gas, food processing, pharmaceuticals, and chemicals benefit significantly from pigging technology. It helps maintain hygiene, reduces product loss, and ensures smooth operations. This article explores the pig system’s working principles, benefits, applications, challenges, and future advancements.

What Is a Pig System?

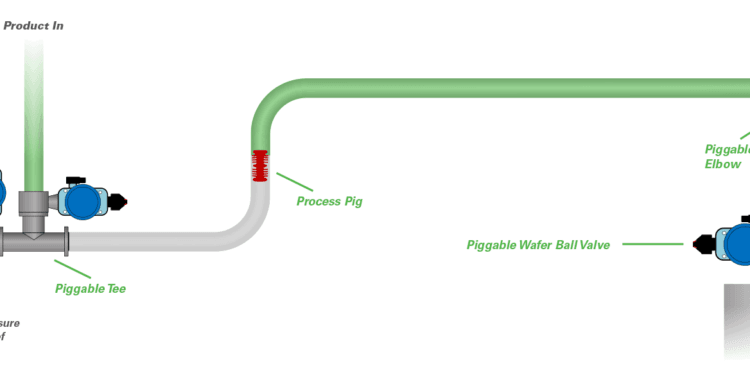

A pig system is a method used to maintain and optimize pipeline operations. It involves inserting a pig—a cylindrical device made of rubber, metal, or plastic—into a pipeline. The pig travels through the pipeline, pushed by gas, liquid, or mechanical force, performing tasks such as cleaning, inspecting, and removing residual materials.

The term “pig” originated from early pipeline cleaning devices that made squealing noises while moving through pipes. Modern pigging systems have evolved significantly, incorporating automation, smart sensors, and advanced materials to improve pipeline efficiency and reliability.

How the Pig System Works

A pig system operates through a series of controlled steps to ensure seamless pipeline management. The process generally includes the following:

- Pig Insertion– The pig is introduced into the pipeline via a launcher.

- Pig Propulsion– The pig moves through the pipeline using liquid, gas, or air pressure.

- Cleaning and Product Recovery– The pig scrapes and removes debris, deposits, or residual product from the pipeline walls.

- Inspection and Monitoring– Advanced pigs equipped with sensors assess pipeline conditions, identifying leaks, corrosion, or blockages.

- Pig Retrieval– The pig is collected at a receiver station and prepared for reuse or maintenance.

Automated pigging systems enhance efficiency by reducing manual labor and optimizing product transfer, cleaning, and inspection.

Components of a Pig System

Several key components ensure the smooth operation of a pig system:

- Pig Launcher– A device that inserts the pig into the pipeline.

- Pipeline Network– The system of pipes through which the pig moves.

- Pig Receiver– A collection station where the pig is removed after completing its operation.

- Propulsion Mechanism– Uses air, liquid, or mechanical force to push the pig through the pipeline.

- Smart Pigs– Equipped with sensors, cameras, or tracking systems for advanced monitoring.

- Control System– An automated setup that regulates pigging operations and ensures process efficiency.

Each component plays a crucial role in improving pipeline maintenance and product handling.

Advantages of Using a Pig System

Maximizing Product Recovery

A pig system minimizes product waste by recovering up to 99% of residual materials in pipelines. This is especially beneficial in industries dealing with high-value liquids such as food products, pharmaceuticals, and chemicals.

Reducing Downtime and Maintenance Costs

Traditional pipeline cleaning methods require shutdowns, leading to production delays. Pigging systems automate cleaning, reducing downtime and lowering maintenance costs.

Enhancing Hygiene and Safety

Industries like food processing and pharmaceuticals require strict hygiene standards. Pigging removes residues that could lead to contamination, ensuring compliance with regulatory standards.

Lowering Environmental Impact

Pigging systems reduce the need for excessive cleaning chemicals, water, and energy, promoting sustainable industrial practices.

Extending Pipeline Lifespan

Regular pigging prevents corrosion, buildup, and blockages, prolonging the lifespan of pipelines and reducing replacement costs.

Improving Efficiency in Batch Production

For industries that switch between different products in pipelines, pigging helps clear previous residues, preventing cross-contamination and ensuring product purity.

Enhancing Workplace Safety

Automating pipeline cleaning and maintenance reduces the need for manual intervention, minimizing the risk of worker exposure to hazardous substances.

Industries That Use Pig Systems

Pigging technology is widely adopted in industries requiring efficient liquid processing, pipeline maintenance, and waste reduction. Some of the major industries include:

Oil and Gas

- Cleaning pipelines of wax, sludge, and debris

- Transporting crude oil, natural gas, and refined products

- Inspecting pipelines for corrosion or structural issues

Food and Beverage

- Cleaning pipelines transporting dairy, juices, sauces, and syrups

- Recovering expensive ingredients and minimizing product loss

- Ensuring hygiene and preventing bacterial contamination

Pharmaceuticals

- Ensuring sterile pipeline transport for liquid medications

- Reducing costly product waste and contamination risks

- Maintaining compliance with strict industry regulations

Chemicals and Paints

- Cleaning pipelines used for chemical and paint production

- Preventing contamination between different batches of chemicals

- Reducing solvent and cleaning agent usage

Cosmetics and Personal Care

- Handling lotions, shampoos, and beauty product pipelines

- Minimizing cross-contamination between different product batches

- Optimizing production efficiency with minimal waste

By implementing pigging systems, these industries achieve enhanced efficiency, cost savings, and improved product quality.

Considerations When Implementing a Pig System

Before installing a pig system, industries must consider several factors to ensure successful implementation:

- Pipeline Design Compatibility– The pig system must be compatible with existing pipeline structures and materials.

- Pig Material Selection– The pig must be made from suitable materials that do not react with the transported product.

- Automation and Monitoring– Integrating smart technologies can optimize pigging operations and improve efficiency.

- Cleaning and Maintenance Schedules– Regular inspections ensure the system operates smoothly and prevents blockages.

A well-planned pigging system enhances operational efficiency and maximizes return on investment.

Challenges of Pigging Systems

Despite their advantages, pigging systems present some challenges:

- High Initial Investment– The cost of installing a pigging system can be significant, but long-term savings make it worthwhile.

- Pipeline Adaptation– Some pipelines require modifications to accommodate pigging systems.

- Training and Expertise– Employees must be trained to operate and maintain the pigging system properly.

By addressing these challenges, industries can fully leverage pigging technology for better efficiency and cost-effectiveness.

Future Trends in Pigging Technology

The pigging industry is continuously evolving with advancements in technology. Some future trends include:

- Smart Pigging with IoT– Internet of Things (IoT) sensors enable real-time monitoring, predictive maintenance, and data analysis.

- Artificial Intelligence (AI) Optimization– AI-driven pigging systems can predict optimal cleaning schedules and enhance pipeline efficiency.

- Eco-Friendly Pig Materials– New biodegradable and sustainable pig materials are being developed to reduce environmental impact.

- Self-Cleaning Pigs– Advanced pigs with self-cleaning features improve efficiency and reduce downtime.

These innovations will further enhance the effectiveness, safety, and sustainability of pigging systems in industrial applications.

Conclusion

A pig system is a vital tool for industries requiring efficient pipeline maintenance, product recovery, and cleaning. By automating processes, businesses can reduce waste, enhance hygiene, and improve productivity. While implementing a pigging system may require an initial investment and training, the long-term benefits outweigh the costs. As technology advances, the pigging industry will continue to evolve, offering smarter, more efficient, and eco-friendly solutions. For companies looking to improve operational efficiency and maintain pipeline integrity, adopting a pig system is a strategic decision that leads to long-term success.