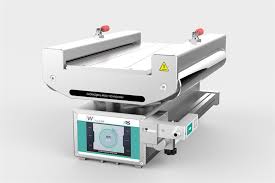

Exploring the Advanced Features of the Arise Web Guiding System

The Arise web guiding system is a sophisticated solution designed to meet the growing needs of industries that depend on the accurate alignment of materials during production processes. Whether in packaging, textiles, printing, or plastics, precision in material handling can make the difference between efficiency and waste. The Arise web guiding system offers advanced technological solutions that ensure high performance and accuracy, contributing to improved production outcomes.

This article will dive into what makes the Arise web guiding system unique, its benefits, and how it can revolutionize industrial production.

What Makes the Arise Web Guiding System Stand Out?

When comparing various web guiding systems in the market, the Arise web guiding system stands out due to its intelligent design, integration of modern technology, and ease of use. This system combines several essential features, allowing industries to streamline their processes rapidly.

- Highly Responsive Sensors: The Arise system integrates cutting-edge sensors that ensure the material always stays aligned. These sensors can detect even the most minor deviations in material position, ensuring continuous production without errors.

- User-Friendly Interface: One of the strong points of the Arise system is its easy-to-use interface. This allows machine operators to monitor and adjust the web guide with minimal training, leading to fewer operational errors and less downtime.

- Customizable Solutions: Unlike standard web guide systems, the Arise system can be customized to meet the specific needs of various industries. This flexibility makes it adaptable to different types of materials and production environments.

How the Arise Web Guiding System Benefits Industrial Operations

Adopting the Arise web guiding system brings several advantages to industries that rely on web-based material processing. Here are some ways it improves operations:

- Enhanced Production Speed: By maintaining accurate web alignment, the Arise system allows for higher production speeds without sacrificing quality. Manufacturers can operate their production lines at optimal speeds, confident that material misalignment won’t disrupt the process.

- Reduced Material Waste: Material misalignment often results in wasted products. The Arise system helps industries minimize waste by ensuring that materials are correctly aligned throughout production. This leads to cost savings and more sustainable operations.

- .

Technological Innovations Embedded in the Arise Web Guiding System

The Arise web guiding system is designed with the latest technological advancements, making it one of the most advanced solutions in the market. Below are some of the innovative features that set it apart:

- AI-Powered Controls: Artificial intelligence (AI) integration allows the Arise system to make real-time decisions about material alignment. It can learn from past production data, continuously optimizing itself for better accuracy and performance.

- Smart Sensor Integration: The sensors used in the Arise system are not just reactive but proactive. These intelligent sensors monitor the material constantly and can predict potential alignment issues before they occur, allowing for preventive corrections.

- Remote Monitoring and Control: The Arise system can be integrated with the Internet of Things (IoT) to allow remote monitoring. Operators can view the system’s performance from any location, making it easier to manage multiple production lines simultaneously.

Maintenance and Longevity of the Arise Web Guiding System

Investing in high-tech equipment like the Arise web guiding system is a significant decision, and companies need assurance that their investment will provide long-term value. The system’s low-maintenance design and durable components remain reliable even after years of operation.

- Self-Diagnostic Features: The Arise system has built-in self-diagnostic features that detect potential issues before they cause breakdowns. This reduces the need for frequent maintenance checks and minimizes downtime.

- Long-Lasting Components: The materials used in the Arise system are highly durable, reducing wear and tear over time. This ensures companies can rely on the system for long-term use without frequent part replacements.

- Minimal Downtime: The combination of intelligent diagnostics and durable design ensures the system experiences minimal downtime, allowing continuous production without interruption.

Industries That Benefit from the Arise Web Guiding System

Several industries can experience significant improvements in efficiency, product quality, and cost-effectiveness by implementing the Arise web guiding system. Here are some of the sectors that benefit the most:

- Printing: In the printing industry, precision is crucial. Even the slightest misalignment can ruin an entire batch of printed materials. The Arise system ensures that the web remains perfectly aligned, allowing printers to operate at high speeds without compromising quality.

- Packaging: Packaging companies deal with materials such as plastic films, paper, and cardboard. Misalignment can lead to defective packaging that cannot be used. The Arise system helps ensure that packaging lines run smoothly and produce high-quality output.

- Textiles: In the textile industry, maintaining the correct fabric alignment as it moves through production lines is essential for ensuring consistent patterns and high-quality finished products. The Arise system’s precise control capabilities help textile manufacturers avoid errors leading to wasted materials.

Future Trends in Web Guiding Technology: How Arise is Leading the Way

The world of web guiding systems is evolving rapidly, and the Arise web guiding system is at the forefront of these advancements. Looking ahead, the following trends are expected to shape the future of web-guiding technology, with Arise continuing to lead the way:

- Autonomous Web Guiding Systems: With AI and machine learning becoming more advanced, web-guiding systems may soon become fully autonomous, requiring minimal human intervention. The Arise system is already paving the way for this future with AI-powered controls and real-time decision-making capabilities.

- Advanced-Data Analytics: Future web guiding systems will incorporate advanced data analytics to provide deeper insights into production processes. The Arise system’s integration with IoT and AI allows real-time data collection and analysis, giving manufacturers actionable insights to optimize their operations.

Conclusion: Why the Arise Web Guiding System is the Future of Industrial Automation

The Arise web guiding system is more than just a solution for maintaining material alignment; it is a powerful tool that can transform industrial production. Its advanced technologies, customization options, and ability to enhance product quality, reduce waste, and lower operational costs make it an essential component of modern manufacturing.

The Arise system will remain at the cutting edge as industries evolve, offering innovative solutions that improve efficiency and drive success. For companies seeking to streamline their operations and stay ahead of the competition, the Arise web guiding system is the ideal choice.