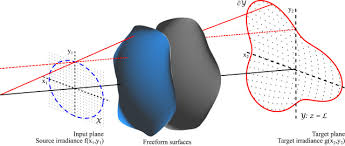

Freeform optics represents a revolutionary advancement in optical design, pushing the boundaries of traditional lenses and mirror shapes to create more versatile and high-performance optical systems. Unlike conventional optics, which rely on simple, symmetrical surfaces, freeform optics uses complex, aspheric surfaces to achieve superior optical performance and design flexibility. This article explores the principles, advantages, applications, and future directions of Freeform Optics, highlighting its transformative impact on various technological fields.

Understanding Freeform Optics

Freeform optics refers to optical components with surfaces that do not conform to standard geometric shapes, such as spheres or cylinders. Instead, freeform optical surfaces can be designed with arbitrary, non-symmetric geometries to address specific optical challenges. This design freedom allows for creating of components optimized for unique applications, providing enhanced performance and capabilities.

- Principles of Freeform Optics: Freeform optics leverages mathematical and computational techniques to design surfaces with complex, non-standard shapes. These surfaces are defined by mathematical functions or algorithms that describe their curvature and shape, allowing for precise control over light propagation and imaging characteristics.

- Manufacturing Techniques: Advances in manufacturing technologies, such as computer-controlled diamond turning and precision polishing, enable the production of freeform optical surfaces with high accuracy. These techniques ensure the complex shapes required for freeform optics are achieved with the necessary surface quality and dimensional precision.

- Characterization and Testing: Accurate characterization and testing are crucial for verifying the performance of freeform optical components. Techniques like interferometry, profilometry, and optical testing systems measure surface accuracy and optical performance, ensuring that initial components meet design specifications.

Advantages of Freeform Optics

Freeform optics offers several critical advantages over traditional optical designs:

- Enhanced Optical Performance: Freeform optics can correct optical aberrations and distortions more effectively than conventional optics. Freeform components can achieve higher image quality and improved performance by tailoring the surface shape to specific optical requirements.

- Design Flexibility: The ability to design arbitrary surface shapes provides greater flexibility in optical system design. Freeform optics can accommodate complex optical paths and integrate multiple functions into a single component, enabling more compact and efficient optical systems.

- Reduced Number of Optical Elements: Freeform optics can combine multiple optical functions into one component, reducing the number of individual lenses and mirrors required. This simplification can lead to more compact and lightweight optical systems.

- Improved Imaging Systems: Freeform optics can enhance imaging systems by providing better control over light distribution and reducing optical aberrations. This improvement is precious in high-resolution imaging applications like telescopes, microscopes, and cameras.

- Customization for Specific Applications: Freeform optics can be tailored to meet the specific needs of various applications, including imaging, illumination, and sensing. This customization ensures that the optical components are optimized for their intended use, resulting in better performance and efficiency.

Applications of Freeform Optics

The versatility of freeform optics has led to its adoption in a wide range of applications across different fields:

- Aerospace and Defense: In aerospace and defense, freeform optics are used in advanced imaging systems, such as space telescopes and surveillance systems. The ability to design custom optical components enhances performance and enables new capabilities in these critical applications.

- Consumer Electronics: Freeform optics are increasingly used in consumer electronics, such as smartphones and augmented reality (AR) devices. Manufacturers can create compact, high-performance devices with improved imaging and display quality by integrating freeform lenses and optical systems.

- Medical Devices: In medical imaging and diagnostics, freeform optics improve the performance of imaging systems, such as endoscopes and optical coherence tomography (OCT) systems. These advancements enable more accurate and detailed visualization of internal structures and tissues.

- Automotive Industry: Freeform optics are used in automotive lighting systems, including headlights and advanced driver-assistance systems (ADAS). Custom-designed optical components provide better illumination, enhanced visibility, and improved safety features.

- Manufacturing and Quality Control: Freeform optics are employed in inspection and quality control systems in manufacturing. These systems use freeform lenses and mirrors to achieve high-precision measurements and inspections of manufactured components.

Challenges and Considerations

While freeform optics offer significant advantages, there are several challenges and considerations associated with their design and implementation:

- Complex Design and Optimization: Designing freeform optical surfaces requires advanced computational tools and algorithms to optimize the surface shape and performance. The complexity of these designs can pose challenges in both design and manufacturing.

- High Manufacturing Costs: The precision required for manufacturing freeform optics can lead to higher production costs. Advanced manufacturing techniques and quality control measures must ensure the components meet design specifications.

- Integration with Existing Systems: Integrating freeform optical components into existing optical systems may require modifications to accommodate their unique shapes and performance characteristics. This integration can involve adjustments to optical mounts, alignments, and system configurations.

- Testing and Quality Assurance: Ensuring the accuracy and performance of freeform optics requires sophisticated testing and quality assurance procedures. These procedures must account for freeform components’ complex geometries and optical properties.

Future Directions in Freeform Optics

The field of freeform optics continues to evolve, with ongoing research and development driving innovations and applications:

- Advanced Computational Design Tools: The development of more advanced computational design tools and algorithms will further enhance the design capabilities of freeform optics. These tools will enable the creation of even more complex and optimized optical components.

- Improved Manufacturing Techniques: Advances in manufacturing techniques and materials will enable the production of freeform optics with higher precision and lower costs. Innovations in fabrication processes will expand the applicability of freeform optics to new industries and applications.

- Integration with Emerging Technologies: Freeform optics will increasingly be integrated with emerging technologies, such as artificial intelligence (AI) and machine learning. These integrations will enhance optical systems’ design, optimization, and performance.

- Broader Applications: As freeform optics technology advances, its applications will continue to expand into new fields, including biotechnology, telecommunications, and energy. The ability to customize optical components for specific needs will drive innovation across various industries.

Conclusion

Freeform optics represents a significant advancement in optical design, offering enhanced performance, flexibility, and customization compared to traditional optical components. By leveraging complex, non-symmetric surface shapes, freeform optics enable the creation of high-performance optical systems for various applications. As technology continues to evolve, freeform optics will play a crucial role in driving innovation and expanding the possibilities of optical systems, shaping the future of various industries and technologies.