Magnetic encoders offer high resolution, precision, reliability, and a long lifespan, making them ideal for demanding environments like engineering machinery where dust, oil, and water are prevalent. The key is to identify genuine Chinese manufacturers to find the most cost-effective encoder magnet. However, sifting through numerous platforms and websites to locate manufacturer-operated stores can be challenging. In short, if you meet the following criteria, your chances of finding a manufacturer exceed 90%.

What is a magnetic encoder magnet?

A magnetic encoder magnet is a crucial component of a magnetic encoder. Magnetic encoders have extensive applications in various industries, such as industrial control, mechanical manufacturing, shipbuilding, textile, printing, aerospace, radar, communication, and military. Mechanical manufacturing is one of the primary application areas for encoders. For instance, in numerical control machine tools, metal cutting machines, and injection moulding machines, encoders provide precise displacement and angular information to ensure the quality and accuracy of components.

Encoder magnets working principle

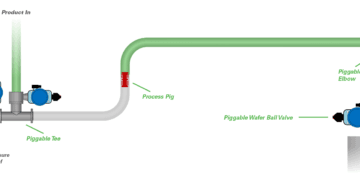

A magnetic encoder utilizes electromagnetic induction to convert physical signals into digital signals for measuring position and angle. A magnetic encoder ring consists of multiple poles fixed to a rotating shaft. Magnetic sensors, typically Hall effect devices or magnetoresistive elements, detect changes in the magnetic field as the ring rotates and convert these changes into electrical signals. A signal processor then converts the electrical signals into digital signals to represent the position and direction of the rotating shaft.

Tip 1: Choose from the primary production regions of encoder magnets.

China is the world’s leading producer of encoder magnets, possessing a complete industrial chain from rare earth mining to magnet manufacturing and export. This unique advantage enables China to offer encoder magnets at more competitive prices than other countries. However, selecting a high-quality encoder magnet supplier in China can be challenging due to the wide range of manufacturers with varying production capabilities. Some factories excel in production processes but lack strong sales capabilities, while others may have excellent sales teams but produce subpar products. This is a common challenge faced by global encoder magnet buyers. To ensure optimal results, purchasers should specify detailed supplier requirements, such as tolerance ranges and magnetic field strength.

Pictured is Hutchinson’s production plant in Suzhou, China. The French multinational corporation has established this facility to manufacture various magnetic encoders and their accompanying components.

Tip 2: Choose suppliers who openly publish encoder magnet specifications.

Many renowned global brands, such as Renishaw (UK), IC-Haus (Germany), Bogen (Germany), Hutchinson (France), and CCmagnetics (China), publicly share their encoder magnet specifications. This transparency makes it easier for buyers to find suitable products. Among these suppliers, Chinese companies, especially CCmagnetics, which caters to businesses of all sizes and research institutions, often offer the most competitive prices. CCmagnetics has a magnet ring query system where you can find the desired specifications by inputting just one or two parameters. After getting the SKU, ask CCmagnetics directly; these magnetic rings do not require mould and magnetizing coil fees.

Tip 3: Find a supplier whose customization capabilities match your specific needs.

If you only need two pairs of poles of radial magnets for a mini motor, there’s no need to get a quote from a factory that can produce IC-Haus magnetic targets. They specialize in high-precision encoder magnets using vulcanized rubber magnet material, which can only be magnetized with precision in China, the US, and Germany. Such suppliers will naturally offer higher quotes. Before contacting suppliers, specify your requirements, including dimensions, tolerances, and precision. This will help match your needs with the supplier’s customization capabilities. Some suppliers, like China’s CCmagnetics, have a broader range of capabilities, from high-precision robot encoder magnets to Hall effect magnets for motor control.

Tip 4: Choose a supplier with comprehensive customization capabilities.

When engineers assemble magnetic encoder devices, they often need to mount the encoder magnet ring onto a shaft. Some suppliers only provide the magnet ring, while others can also customize the metal carrier for the magnet ring. Sourcing the magnet ring and the metal carrier from two different suppliers can significantly increase both procurement and communication costs. It’s more efficient to choose a single supplier that can handle the entire process, from initial design confirmation to the final delivery of the assembled magnet ring. This approach reduces costs and ensures the quality of the final product.

Tip 5: Use drawings or animations for effective communication.

Due to language and cultural differences, the term “encoder magnet ring” varies across countries. For example, in China, it’s called “magnetic encoder ring,” while in some countries, it’s known as “rotary magnetic scales” or “magnetic targets”, as used by IC-Haus. It’s best to use drawings or animations to convey your specific requirements to avoid misunderstandings. Additionally, using English as the primary language for communication can help ensure clarity.

_for_IC-MU128,_compared_to_the_blueprint.jpg)

Tip 6: Don’t let past impressions or media influence your judgment.

China’s technological capabilities and manufacturing processes in the encoder magnet ring industry are advancing at an unprecedented rate. Ten years ago, only companies like Bogen and IC-Haus could achieve the precision that some Chinese suppliers can now match, often at a more competitive price. This explains why Hutchinson established a factory in Suzhou, China. China’s encoder magnet manufacturing industry has experienced rapid growth in recent years. While the market faced challenges due to COVID-19 and the overall OEM industry slowdown in 2020, it is projected to exceed $460 million by 2025. Some suppliers may claim to use European or American processes and certifications like SGS and CE, but they may source their products from China to maximize profits.

Tip 7: Use small-batch orders to test the supplier’s overall supply and quality control capabilities during the cooperation.

After finding a suitable encoder magnet supplier, most purchases start with sample testing to ensure product quality. Then comes the large-scale order. This process can be optimized by adding a step: purchase a small batch after testing the initial sample and conduct another round of testing. Only then should you proceed with the large-scale order. This intermediate step helps ensure the supplier’s supply capacity meets your production needs. This step may not be as critical for small and medium-sized teams with a smaller demand for encoder magnets.